- Produce and incorporate uniform nanocrystals, nanoemulsions, and liposomes into cosmetic products.

- Manufacture creams, gels, lotions, topicals, ointments, moisturizers, and patches with enhanced transdermal drug delivery properties.

- Improve UV filtration properties and optical translucency of sunscreens and moisturizers.

Overview

Cosmetic products, such as creams, gels, lotions, topicals, ointments, sunscreens, moisturizers, and patches, incorporating nanocrystals, nanoemulsions, and liposomes are increasingly used as delivery systems for active lipophilic compounds and UV blockers. The ability of nanoparticles to efficiently transport active agents through the skin gives these products a wide range of therapeutic properties, ranging from enhanced systemic drug delivery to skin hydration and wound healing. The application of nanomaterials in sunscreens and moisturizers takes advantage of enhanced UV filtering properties of titanium dioxide (TiO2) and zinc oxide (ZnO) nanosuspensions and ensures a higher degree of optical translucency and better absorption by the skin.

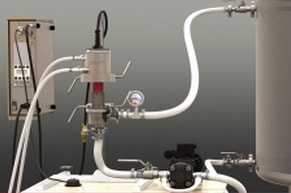

Industrial Sonomechanics® patented Barbell Horn® Ultrasonic Technology (BHUT)-based laboratory, bench, and industrial ultrasonic liquid processors make it easy to produce and incorporate nanomaterials into a wide range of cosmetic products, guaranteeing reproducible and predictable results at any scale of operation.

Industrial Sonomechanics® patented Barbell Horn® Ultrasonic Technology (BHUT)-based laboratory, bench, and industrial ultrasonic liquid processors make it easy to produce and incorporate nanomaterials into a wide range of cosmetic products, guaranteeing reproducible and predictable results at any scale of operation.

Case Studies & Application Reports

All-Natural CBD Extract Nanoemulsion

Translucent Oil-in-Water Nanoemulsions

Cosmetic and Dermatological

Blog Posts

12/19/23

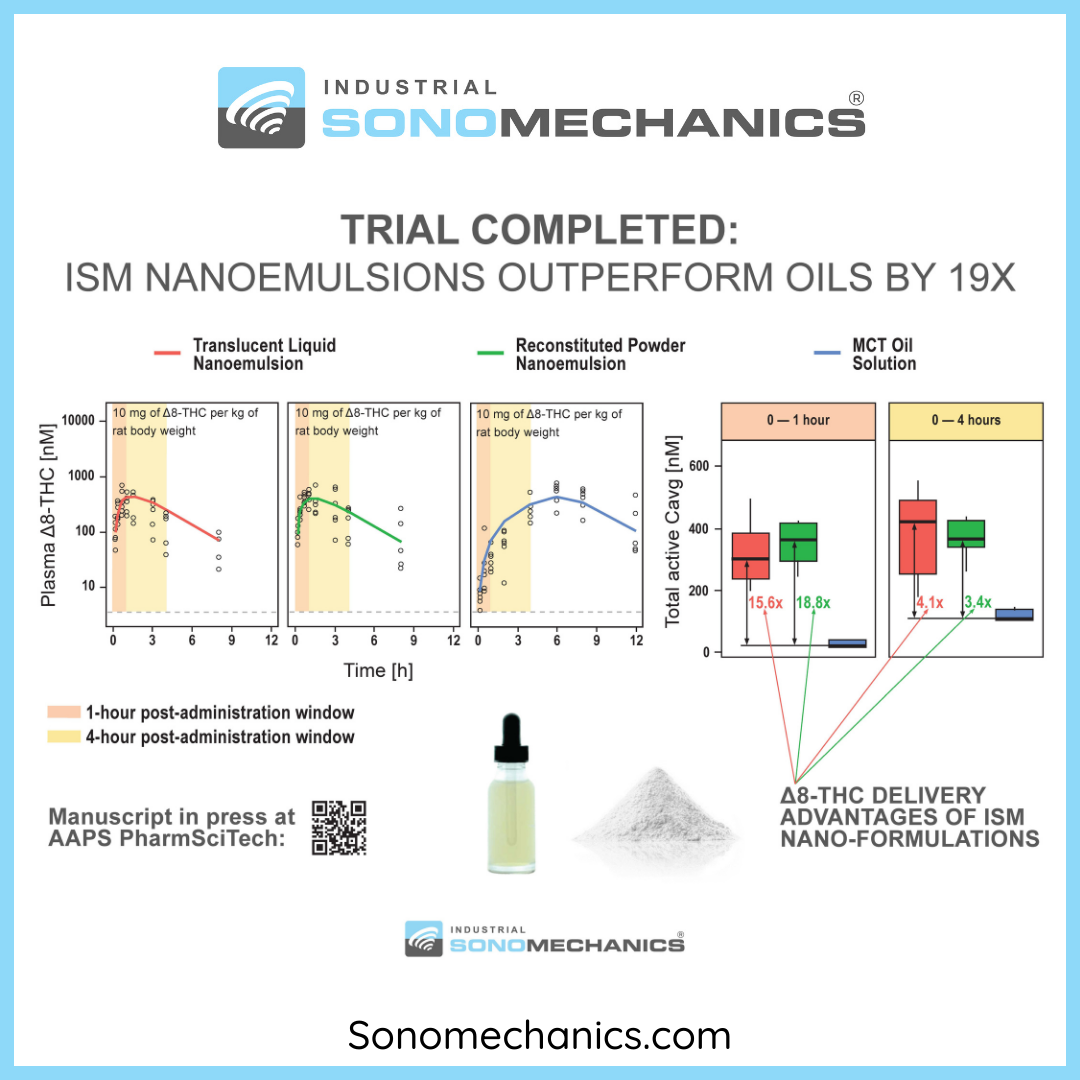

ISM Publishes a Groundbreaking PK Study of Two Δ8-THC Nanoemulsions

Industrial Sonomechanics® (ISM) has recently completed a groundbreaking pre-clinical pha... Read more...

03/03/23

ISM Will Be Presenting at the 2023 NECANN in Boston, MA

We are excited to announce that Industrial Sonomechanics (ISM) will participate in the 2...

Read more...

11/01/22

ISM Will Be Participating in 2022 Wonderland Event in Miami, FL

We are excited to announce that Industrial Sonomechanics (ISM) will participate in the 2...

Read more...

Customer Testimonials

Dominic Notter, Matrix of Life

“ISM supplied us with their industrial-scale ultrasonic processor, ISP-3000, which we have been using to make nutraceutical and cosmetic products, as well as for essential oil extraction and several similar applications for over a year. We are pleased to say that with this processor, the efficiency of plant oil extraction, emulsification and solids’ dispersion is superb, enabling us to make products comprising dozens of different oils, solid powders and water. The products seem to remain permanently stable and have many other enhanced properties: our customers consistently report superior taste, texture and overall performance. We look forward to using this technology for developing many new processes in the near future.”