What is ISM?

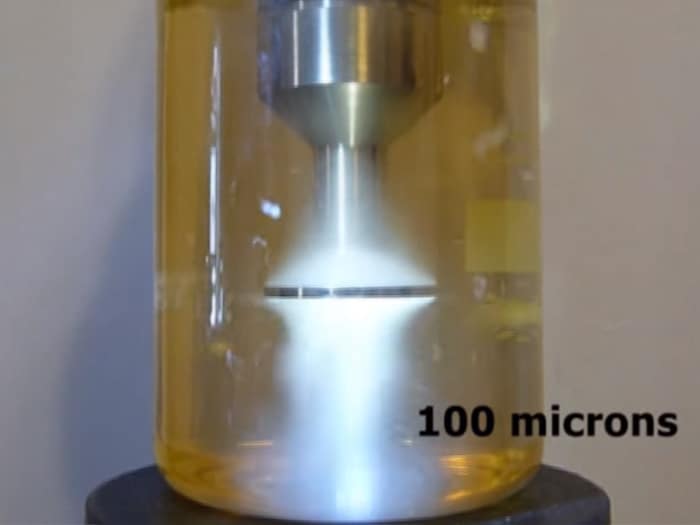

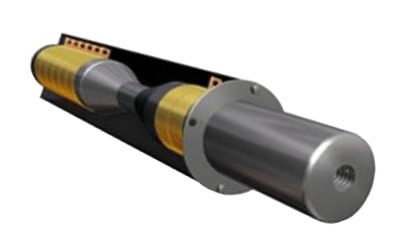

ISM is a research & development, equipment design and process consulting firm, specializing in high-power ultrasonic technology for liquid treatment. ISM offers bench and commercial-scale ultrasonic liquid processors, also called ultrasonic homogenizers, ultrasonic mixers, sonochemical reactors or ultrasonic wet milling systems, able to provide unprecedented processing rates and product quality. Application examples include the production of nanoemulsions, liposomes, nanocrystals and wax nanoparticles for cannabis, pharmaceutical, cosmetic, food, ink, paint, coating, wood treatment, nanocomposite, pesticide, and fuel industries. In addition, we are actively involved in plant oil extraction, liquid degassing, cell disruption, polymer and epoxy processing, and more.

Our Mission

An Active R&D Firm

- Manufacturing of uniform nanoemulsions to make cannabis extracts water-compatible for increased bioavailability and faster onset of action.

- Water extraction of oils and active pharmaceutical ingredients by controlled cell disruption (lysis).

- Investigating the effects of high-intensity ultrasound for degassing of liquids.