- Disperse, deagglomerate and wet-mill pigment particles down to the nanometer range.

- Improve color strength, hiding power, scratch, crack and UV resistance, surface finish, and durability of inks, paints, varnishes, and coatings.

- Simultaneously reduce particle sizes and remove entrapped air and/or dissolved gasses from the pigment suspension medium.

Overview

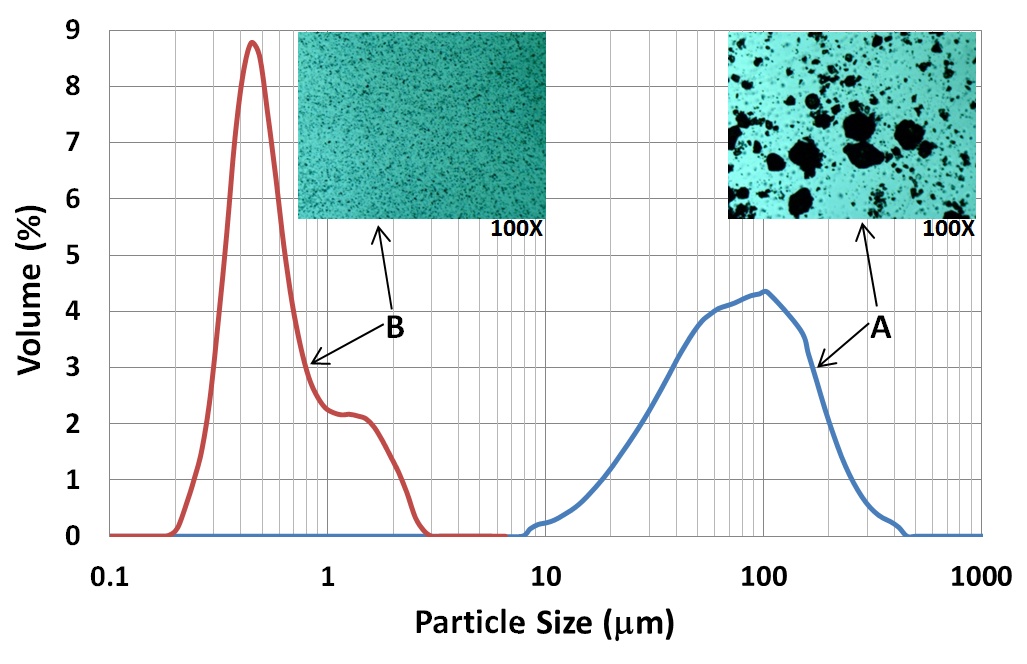

Pigments are, most commonly, insoluble metal oxide particles (e.g., TiO2, ZrO2, SiO2, CeO2, and ZnO) that, when dispersed in an appropriate medium, can provide color. Depending on the medium, pigment dispersions are used as inks, varnishes, coatings, paints, etc. Many of the critical properties of these products, such as the color strength, hiding power, surface finish, and durability, are determined by the sizes of the dispersed pigment particles. Since the color strength depends on the cumulative exposed pigment surface area, it can be substantially enhanced by reducing and homogeneously dispersing the particles. Pigment particle size reduction can also improve scratch, crack and UV resistance of inks, coatings, varnishes, and paints because it leads to closer particle packing and their better incorporation into the binding medium.

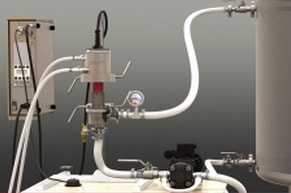

Industrial Sonomechanics® ultrasonic processors provide a convenient means for dispersing, deagglomerating and wet-milling pigment particles down to the required nanometer size range, while simultaneously removing any entrapped air and/or dissolved gasses (degassing) from the suspension medium. With our patented Barbell Horn® Ultrasonic Technology (BHUT), these processes can be easily implemented at any scale, guaranteeing reproducible and predictable high-quality results.

Industrial Sonomechanics® ultrasonic processors provide a convenient means for dispersing, deagglomerating and wet-milling pigment particles down to the required nanometer size range, while simultaneously removing any entrapped air and/or dissolved gasses (degassing) from the suspension medium. With our patented Barbell Horn® Ultrasonic Technology (BHUT), these processes can be easily implemented at any scale, guaranteeing reproducible and predictable high-quality results.

Blog Posts

12/14/17

Ultrasonic Nano-Crystallization of Salsalate for Improved Bioavailability

Salsalate is part of a class of naturally occurring chemicals known ...

Read more...

10/06/16

Ultrasonic Dispersing and Wet-milling of Calcium Carbonate (CaCO3)

Cement, and its paved derivative, concrete, is a widely-consumed mat... Read more...

01/02/16

Acoustic Cavitation: The Driving Force Behind Ultrasonic Processing

Liquids exposed to high-intensity ultrasound can undergo acoustic ca... Read more...

Customer Testimonials

Petri Jokiranta, Managing Director, Adpap Ltd.

“Adpap Ltd. is a pulp and paper, paint, chemical, raw material and additive process expert with clients around the world. We have been using ISM`s ISP-3000 industrial system since 2014. We have successfully implemented their equipment in several of our processes and are very satisfied with the results. ISM has been excellent in responding to questions and addressing any of our concerns. We look forward to working with them on many upcoming projects in the near future.”