- Efficiently extract valuable nutraceutical ingredients, including alkaloids, vitamins, lactones, polysaccharides, polyphenols, terpenoids, cannabinoids, and more.

- Produce water-soluble liquid and powdered nano-formulations on lab, bench and industrial scales.

- Greatly increase the bioavailability and accelerate the onset of action of active nutraceutical ingredients.

Overview

The nutraceutical industry continuously strives to improve procedures used for extracting natural bioactive ingredients from plants and mushrooms, as well as for formulations that enhance the bioactives’ therapeutic performance, pharmacokinetic profiles, safety, stability, taste, and appearance. In particular, significant interest exists in formulating these ingredients as water-soluble liquids and powders, which, besides making them much more bioavailable and fast-acting, allows them to be readily infused and remain stabile in finished beverage and food products. Hundreds of manufacturers in the nutraceutical space have been able to achieve these goals by taking advantage of Industrial Sonomechanics’ (ISM) ultrasonic equipment, all-in-one formulations, and consulting services.

Many successful products on the market today are produced with ISM’s technology. Our clients have created fast-acting functional beverages, gummies, chewable and effervescent tablets, tinctures, sprays, shots, sachets, instant powder mixes, and many other products infused with alkaloids, curcuminoids, cannabinoids, kavalactones, coenzymes, vitamins, polyphenols, polysaccharides, cannabinoids, and other bioactives.

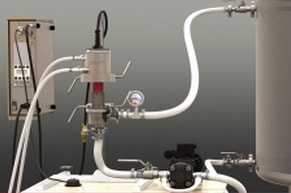

By leveraging Industrial Sonomechanics® patented Barbell Horn® Ultrasonic Technology (BHUT), these processes can be seamlessly integrated into operations of any scale, ensuring consistent and reliable high-quality outcomes.

Many successful products on the market today are produced with ISM’s technology. Our clients have created fast-acting functional beverages, gummies, chewable and effervescent tablets, tinctures, sprays, shots, sachets, instant powder mixes, and many other products infused with alkaloids, curcuminoids, cannabinoids, kavalactones, coenzymes, vitamins, polyphenols, polysaccharides, cannabinoids, and other bioactives.

By leveraging Industrial Sonomechanics® patented Barbell Horn® Ultrasonic Technology (BHUT), these processes can be seamlessly integrated into operations of any scale, ensuring consistent and reliable high-quality outcomes.

Case Studies & Application Reports

Ultrasonic Disruption of Yeast Cells

Scalable Production of Natural Mushroom Extracts

Scaling Up the Production of a Nanoemulsion with BHUT

All-Natural CBD Extract Nanoemulsion

Blog Posts

04/14/25

How Stable Are Nanoemulsions Made with NanoStabilizer®-LT and NanoStabilizer®-LSO? Here's the Data.

One of the most common questions we receive from customers is about the long-term stabil... Read more...

02/12/25

Using a High-Pressure Homogenizer? Produce Superior Nanoemulsions with All-In-One NanoStabilizers®

All-In-One NanoStabilizers® have transformed the cannabis and nutraceutical industries b... Read more...

02/03/25

Highly Concentrated Nanoemulsions With Sub-100 nm Droplets: Here’s How to Make Them

Producing fast-acting, highly bioavailable, readily water-soluble nanoemulsions of bioac... Read more...

Customer Testimonials

Dominic Notter, Matrix of Life

“ISM supplied us with their industrial-scale ultrasonic processor, ISP-3000, which we have been using to make nutraceutical and cosmetic products, as well as for essential oil extraction and several similar applications for over a year. With this processor, the efficiency of plant oil extraction, emulsification and solids’ dispersion is superb, enabling us to make products comprising dozens of different oils, solid powders and water. The products seem to remain permanently stable and have many other enhanced properties: our customers consistently report superior taste, texture and overall performance.”