ULTRASONIC HORN WITH A LARGE HIGH-AMPLITUDE OUTPUT SURFACE

Abstract

Ultrasonic horns having improved longevity and simplified manufacturing approaches that can be more easily adapted to ultrasonic reactor chambers or batch processing containers. The ultrasonic horn designs increase the uniformity and intensity of acoustic energy radiated into a liquid medium and thus better correspond to the requirements of a particular sonochemical or sonomechanical process. The ultrasonic horns do not require a specific number of cylindrical sections and allow for various lengths and profiles of variable-diameter sections. The ultrasonic horns also reduce stress in the material of the ultrasonic horns and therefore extend longevity.ULTRASONIC HORN WITH A LARGE HIGH-AMPLITUDE OUTPUT SURFACE

Abstract

Ultrasonic horns having improved longevity and simplified manufacturing approaches that can be more easily adapted to ultrasonic reactor chambers or batch processing containers. The ultrasonic horn designs increase the uniformity and intensity of acoustic energy radiated into a liquid medium and thus better correspond to the requirements of a particular sonochemical or sonomechanical process. The ultrasonic horns do not require a specific number of cylindrical sections and allow for various lengths and profiles of variable-diameter sections. The ultrasonic horns also reduce stress in the material of the ultrasonic horns and therefore extend longevity.SYSTEME DE REACTEUR A ULTRASONS A HAUTE CAPACITE

Abstract

An ultrasonic reactor system with an appropriately designed reactor chamber used in conjunction with a compatible ultrasonic Barbell Horn or its derivative that provides a significant efficiency increase and an intensification of sonochemical and sonomechanical processes is disclosed. These enhancements arise from the ability of the reactor chamber to direct all treated liquid media through the highly active ultrasonic cavitation region located near the surface of the horn, as well as from several improvements in the Barbell Horn design that significantly increase its longevity and in its output surface area, thereby increasing the total size of the active cavitation region.EFFICIENT COOLING OF PIEZOELECTRIC TRANSDUCERS

Abstract

A sealed piezoelectric transducer having a single, uniform, electrically insulating, heat-conducting layer of a soft, rubbery material filled with a fine, homogeneously-dispersed powder having high thermal conductivity. The material is placed in contact with the surfaces of the transducer and conducts the heat from the surfaces to an external heat sink. Since the thermally conductive powder is fully encapsulated in the rubbery material, its abrasive properties are neutralized. The softness of the material ensures that the vibration of the transducer does not transmit significant acoustic energy into the material, thereby avoiding the generation of parasitic heat. In addition, the layer fills the entire gap between the transducer and the heat sink, thereby removing any possibility of moisture-related arcing.HIGH CAPACITY ULTRASONIC REACTOR SYSTEM

Abstract

An ultrasonic reactor system with an appropriately designed reactor chamber used in conjunction with a compatible ultrasonic Barbell Horn or its derivative that provides a significant efficiency increase and an intensification of sonochemical and sonomechanical processes is disclosed. These enhancements arise from the ability of the reactor chamber to direct all treated liquid media through the highly active ultrasonic cavitation region located near the surface of the horn, as well as from several improvements in the Barbell Horn design that significantly increase its longevity and in its output surface area, thereby increasing the total size of the active cavitation region.ULTRASONIC ROD WAVEGUIDE-RADIATOR

Abstract

The present invention comprises an ultrasonic resonant rod waveguide-radiator with at least three cylindrical sections, one of which is an entrance section having a planar entrance surface and another of which is an exit section having a planar exit surface, and at least two sections having a variable cross-section. The cylindrical sections and sections of variable cross-section are arranged in alternating fashion and connected to each other acoustically rigidly. The dimensions of the cylindrical sections and the sections of variable cross-section are selected so that the gain of the waveguide-radiator is significantly greater than unity and the strain created by passage of ultrasonic waves through the waveguide-radiator is minimized, increasing the operational life of the waveguide-radiator and maximizing the amount of useful energy transmitted by the waveguide-radiator.TRADEMARK: INDUSTRIAL SONOMECHANICS

Abstract

CLASS 7: Laboratory, bench and industrial-scale ultrasonic processors used for sonication, liquid processing, homogenization, sonochemistry, mixing, emulsification, extraction, degassing, disintegration, disinfection, cell disruption, pasteurization, dispersing, deagglomeration, desulfurization, wet-milling, nanoparticle production, cavitation, and ultrasonic welding, cutting, drilling and soldering. CLASS 42: Development of new technology for others in the field of ultrasonic liquid processor-assisted physical and chemical process development as it pertains to testing and results dissemination on the efficacy of ultrasound processing, process improvement consulting in the field of ultrasonic processing, custom ultrasonic equipment development and integration; Materials testing and evaluation; Product testing; Scientific and technological services, namely, development of new technology for others in the field of ultrasonic liquid processors-assisted development as it pertains to physical and chemical processes. FIRST USE 2-8-2006; IN COMMERCE 2-8-2006 SER. NO. 87-080,614, FILED 06-22-2016Trademark: NANOSTABILIZER

Abstract

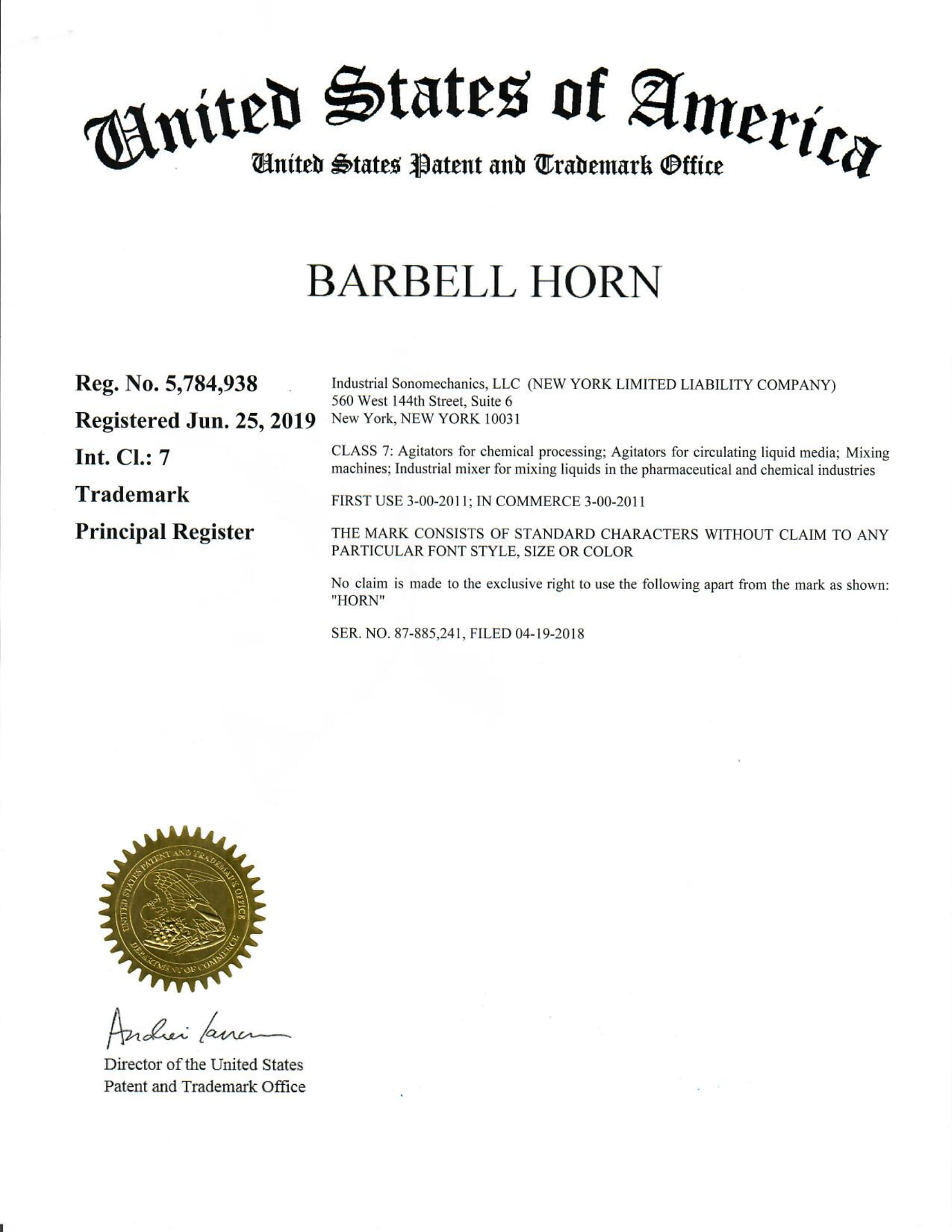

IC 001. US 001 005 006 010 026 046. G & S: Chemical additives for use in the manufacture of cosmetics; Chemical additives for use in the manufacture of food; Chemical additives for use in the manufacture of pharmaceuticals; Chemical products for stabilising foodstuffs; Emulsifiers for industrial purposes; Emulsifiers for use in the manufacture of foods; Excipients for use in the manufacture of pharmaceuticals, nutraceuticals, food, beverages, and cosmetics; Food preserving chemicals; Preservatives for use in the pharmaceutical industry; Non-ionic surfactants as raw materials for use in the manufacture of industrial products, consumer and household products. FIRST USE: 20180423. FIRST USE IN COMMERCE: 20180423Trademark: Barbell Horn

Abstract

CLASS 7: Agitators for chemical processing; Agitators for circulating liquid media; Mixing machines; Industrial mixer for mixing liquids in the pharmaceutical and chemical industries