ISM offers high-amplitude ultrasonic processors for upgrading petroleum fuels by sulfur removal (desulfurization), emulsification with water (production of emulsion fuels) and degassing, significantly increasing the value of the fuels and reducing many of their harmful environmental and health effects.

Overview

Crude oil contains many toxic sulfur compounds that must be removed to ensure that crude oil-derived petroleum fuels comply with current environmental regulations. High-amplitude ultrasound-assisted oxidative desulfurization is an effective alternative technology to traditional sulfur removal by hydrotreating, allowing the process to be carried out under milder conditions, faster, safer and much more economically.

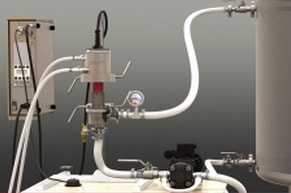

Burning petroleum fuels (e.g., in power boilers, marine and truck diesel engines) produces many greenhouse gasses and pollutants (nitrous oxides, hydrocarbons, carbon monoxide, carbon dioxide, particulate matter, black smoke, etc.), harming human health and the environment. Nano-emulsifying a small amount of water into the fuels significantly reduces these harmful emissions by lowering the local flame temperature and making the fuels burn more completely. The resulting emulsion fuels have greater combustion efficiency and can be used in unmodified boilers or engines.

Petroleum jet fuel is used to cool various engine and airframe components in commercial and military aircraft. If dissolved oxygen is present in the thermally stressed fuel, deposits are formed in various vital aircraft devices (fuel system actuators, injectors, nozzles, spray bars, fuel lines), obstructing the flow and potentially causing catastrophic failure of the fuel system. The removal of dissolved oxygen from the fuel by ultrasonic degassing makes it thermally stable and prevents the formation of these deposits.

Burning petroleum fuels (e.g., in power boilers, marine and truck diesel engines) produces many greenhouse gasses and pollutants (nitrous oxides, hydrocarbons, carbon monoxide, carbon dioxide, particulate matter, black smoke, etc.), harming human health and the environment. Nano-emulsifying a small amount of water into the fuels significantly reduces these harmful emissions by lowering the local flame temperature and making the fuels burn more completely. The resulting emulsion fuels have greater combustion efficiency and can be used in unmodified boilers or engines.

Petroleum jet fuel is used to cool various engine and airframe components in commercial and military aircraft. If dissolved oxygen is present in the thermally stressed fuel, deposits are formed in various vital aircraft devices (fuel system actuators, injectors, nozzles, spray bars, fuel lines), obstructing the flow and potentially causing catastrophic failure of the fuel system. The removal of dissolved oxygen from the fuel by ultrasonic degassing makes it thermally stable and prevents the formation of these deposits.

Case Studies & Application Reports

Production of Emulsion Fuels

Crude Oil Desulfurization

Blog Posts

04/10/16

Acoustic Cavitation: Visual Examples of Chemical & Physical Processes

In our previous blog post on ultrasonic cavitation in liquids, we de... Read more...

01/02/16

Acoustic Cavitation: The Driving Force Behind Ultrasonic Processing

Liquids exposed to high-intensity ultrasound can undergo acoustic ca... Read more...

12/01/15

6 Frequently Used Terms in Ultrasonic Processing of Liquids

This blog post focuses on six common terms used in conjunction with ... Read more...

Customer Testimonials

Ed Urquhart, President & CEO at Vernay

“As former CEO of Markisches Werk Halver (MWH) I have had the opportunity to work with ISM, its staff, and its patented Barbell Horn Ultrasound Technology for several years. MWH is a leading manufacturer and technology development company located in central Germany. During my tenure there, we identified ISM as a company with strong management and technical expertise, together with a unique and sustainable technology advantage. ISM’s Barbell Horn technology allows large horn output diameters in combination with high horn gains to optimally match the transducer to the load, enabling high intensity laboratory setups to be implemented on an industrial scale. MWH supplied ultrasound equipment to SulphCo, Inc., an Amex listed company with a technology for using ultrasound to remove sulfur from crude oil and distillates. As a long-time director on SulphCo’s Board, I was able to witness first hand that ISM’s approach and patented technology were instrumental in evolving from a laboratory scale to a commercial scale in this demanding application. As a technically trained engineer, I believe that ISM has the experience and the technology applicable in multiple industries, including algae processing for biofuels manufacturing, emulsion and dispersion production, wastewater treatment, etc. I look forward to many new great things from ISM and would recommend them without hesitation.”