Presentations & Technology Videos:

-

Process Expo 2023 – Water-Soluble Bioactives: Benefits & Production

-

Newest Advancements in ISM Ultrasonic Technology and Nano-Formulations

-

NECANN Recording: Water-Soluble Cannabinoids, Alkaloids & Other Bioactives

-

Sound Enclosure for Ultrasonic Processors – Open vs. Closed Sound Levels

-

Sound Enclosure for Ultrasonic Processors – Introduction to NRE-30

-

Podcast: Make and Measure the Potency of Cannabis Extract Nanoemulsions

-

Plant 2 Product: Podcast with ISM and Extrakt Labs

-

“Water-Soluble” Cannabis: Ultrasonic Production of Liquids & Powders

-

Industrial Sonomechanics® at MJBizCon 2021 in Las Vegas, NV

-

Water-Soluble Cannabis Extract Nanoemulsions, by Dr. Alexey Peshkovsky

-

Water Compatible Nanoemulsions The Battle of Formulations

-

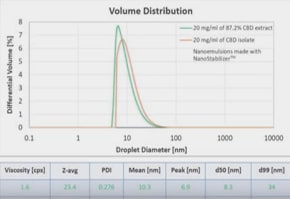

Analysis, Optimization and Production of Translucent Nanoemulsions

-

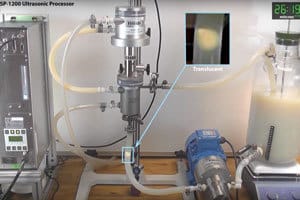

Commercial Production of Water-Soluble THC and CBD by High-Intensity Ultrasound

-

Why and How to Make Cannabis Extracts “Water-Soluble”

-

Interview with Dr. Alexey Peshkovsky at 2021 CBDExpo

-

Dr. Alexey Peshkovsky speaking at the University of Cauca, Colombia

-

Barbell Horn Ultrasonic Technology Introduction and How We Scale Up

-

Industrial Sonomechanics® at the 2020 White Label Expo, Highlights

-

Webcast Recording: Ultrasonic Cannabis Oil Nano-Emulsification & Extraction

-

Interview with Dr. Alexey Peshkovsky by Sveltia

-

Industrial Ultrasonic Liquid Processor, ISP-3000, with Transparent Reactor Chamber

-

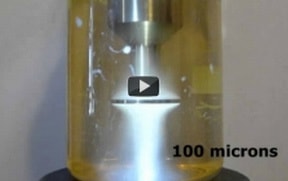

Ultrasonic Cavitation in Water Produced by HBH-type Barbell Horn, Tip Ø = 35 mm

-

Ultrasonic Cavitation in Water Produced by FBH-type Barbell Horn, Tip Ø = 35 mm

Instructional Videos:

-

LSP-600 Ultrasonic Processor, Flow-Through: Unboxing and Assembly Instructions

-

Large-Capacity In-Line Filter: Assembly, Filtration, Cleaning, & Storage Procedures

-

Barbell Horn® Replacement Procedure for ISM Ultrasonic Processors

-

LSP-600 Ultrasonic Processor, Batch Mode: Unboxing & Assembly Instructions

-

Cone-Bottom Storage/Mixing Tank: Assembly Instructions

-

Switching from Flow-Through to Batch Configuration on BSP-1200 processor

-

Assembly Procedure for ISP-3000 Industrial-Scale Ultrasonic Liquid Processor

-

Disassembly Procedure for ISP-3000 Industrial-Scale Ultrasonic Liquid Processor

-

Disassembly & Assembly of LSP-500 Lab Ultrasonic Processor: Flow-Through Mode

-

Disassembly & Assembly of LSP-500 Lab Ultrasonic Processor: Batch Mode

-

Disassembly & Assembly of BSP-1200 Bench-Scale Ultrasonic Processor

Processes Demonstration Videos:

-

ISM Storage/Mixing Tanks Comparison: Single vs. Dual Magnetically Coupled Mixer

-

Dosing ISM’s Liquid and Powdered Nano-formulations Into Water

-

Ultrasonic Degassing of High-Viscosity Acrysol Coating with BSP-1200

-

Ultrasonic Degassing of 3% Chitosan Acetate Using ISM LSP-600

-

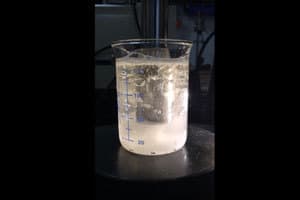

Dosing a Translucent Cannabis Extract Nanoemulsion into Water

-

Ultrasonic Production of Translucent Cannabis Extract Nanoemulsion

-

Can CBD or THC be Made Water-Soluble?

-

Coffee Infused With Water-Soluble CBD Nanoemulsion

-

Ultrasonic Degassing of Polyurethane

-

Ultrasonic Degassing Test with LSP-500 Processor, Batch Mode

-

Ultrasonic Degassing & Deaeration of a High-Viscosity Liquid

-

Ultrasonic Foam Stimulation in Bottled Beer with Barbell Horn

-

Ultrasonic Degassing of Water with Detergent

-

Translucent Nanoemulsion Produced with ISP-3000

-

Translucent Water in Oil Nanoemulsion with LSP-500, Batch Mode

-

Ultrasonic Degassing of Heavy Industrial Gear Oil

-

Ultrasonic Removal of Air Bubbles from Epoxy Resin

-

Acoustic levitation using Industrial Sonomechanics’ Barbell horn

-

Acoustic levitation using Industrial Sonomechanics’ Barbell horn

-

Ultrasonic Degassing of Thickened Apple Juice with LSP-500 (Batch Mode)

-

Ultrasonic Dispersing of Carbon Nanotubes

-

Ultrasonic Degassing and Deaeration of a High-Viscosity Liquid

-

Ultrasonic Dispersion of Carbon Black in Water, 750 ml Batch

-

Ultrasonic Dispersion of Carbon Black in Water, 10 Liter Batch

-

Degassing & Deaeration of Paraflex HT5 oil, Batch Mode

-

Algae Oil Extraction Using High-Intensity Ultrasound

Q&A Video Series:

-

Q&A with Dr. A. Peshkovsky: What is Unique About ISM Ultrasonic Liquid Processors?

-

Q&A with Iva: Choosing the Right Ultrasonic Processor for Making Nanoemulsions

-

Q&A with Alexey: Are High Ultrasonic Amplitudes Important?

-

Overview of Nano-Emulsification with BSP-1200 Processor & NanoStabilizers

-

Do I Need Technical Background to Make Nanoemulsions with ISM Technology

-

Possible Nanoemulsion Concentration & How They Affect Droplet Sizes & Translucency

-

Q&A with Shlomo: What is the Shelf Life of Nanoemulsions Made with NanoStabilizer®?

-

Q&A with Alexey: How Do I Make a Water-soluble Cannabis Nanoemulsion Powder?

-

Q&A with Shlomo: Why Do I Need to Filter Nanoemulsions & What Type of Filter To Use?

-

Q&A with Pavel: Switching from Flow-Through to Batch Configuration on BSP-1200

-

Q&A with Dr. Alexey: What is Ultrasonic Degassing & What Industries Does it Benefit?

-

Q&A with Jeff: Do You Offer an All-Natural and/or Organic Nanoformulation?

-

Q&A with Alexey: Overview of Nano-emulsification with the ISP-3600 Processor

-

Q&A with Jeff Meyer: Does ISM Manufacture Nanoemulsions?

-

Q&A with Jeff Meyer: Nanoemulsion Formulations-“Make” vs. “Buy”

-

Q&A with Dr. Peshkovsky: What Are the Most Common Water-Compatible Formulations?

-

Recommended Bioactive Concentrations & NanoStabilizer to Bioactive Ratios

-

Nanoemulsions, Macroemulsions, Microemulsions & Liposomes Defined