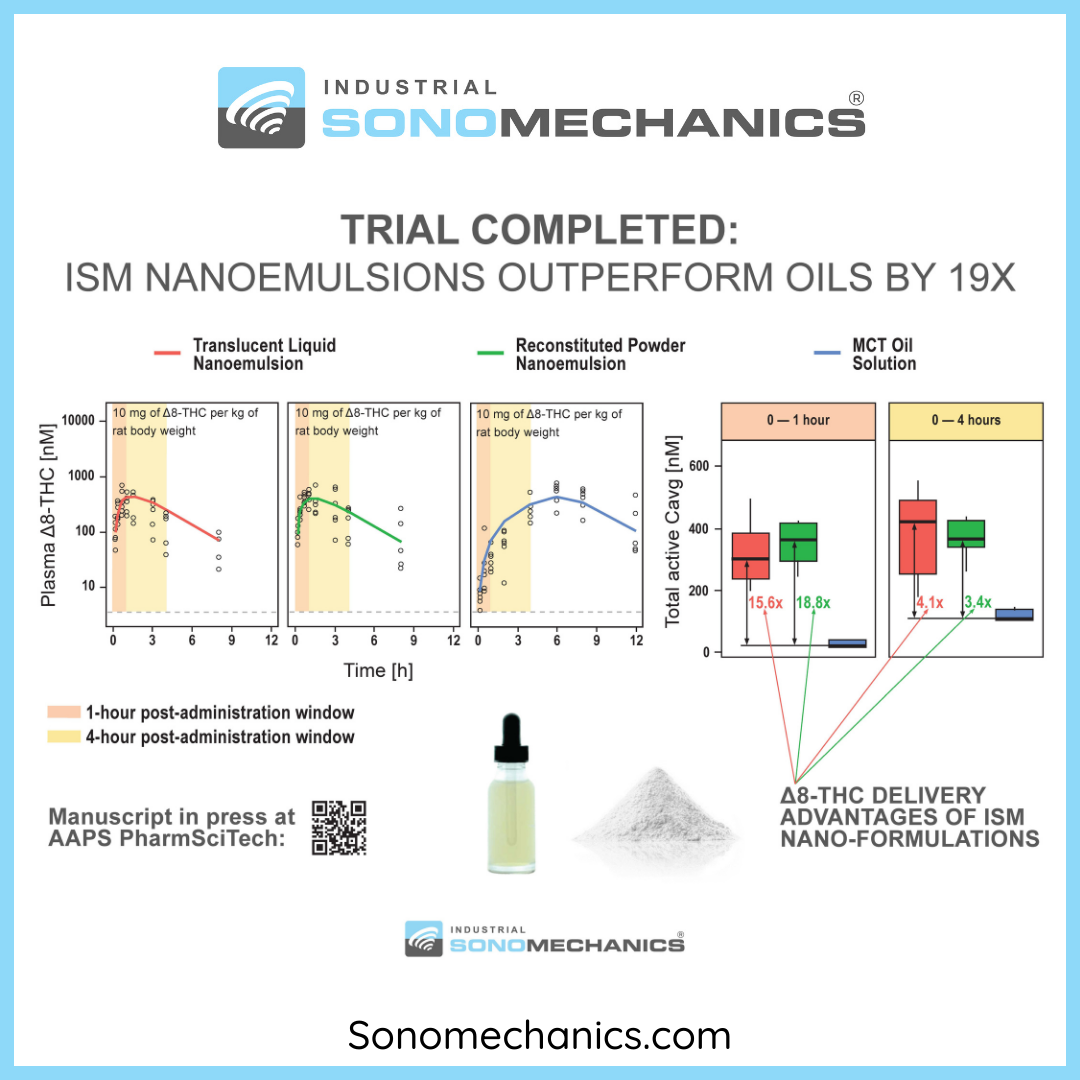

Industrial Sonomechanics® (ISM) has recently completed a groundbreaking pre-clinical pharmacokinetic study, comparing two orally administered Δ8-THC nanoemulsions (liquid and powdered) with a Δ8-THC solution in MCT oil. The results demonstrate considerable advantages of nanoemulsions produced with ISM's ultrasonic equipment and NanoStabilizers®, and are detailed in our latest manuscript, currently in press at AAPS PharmSciTech, an official journal of The American Association of Pharmaceutical Scientists.

This marks the industry's first pre-clinical study of Δ8-THC nanoemulsions, which was conducted and published in collaboration with Verdient Science, LLC.